In industrial boiler plants, efficiency gains rarely come from sweeping changes. They come from capturing value that is already there. One of the most effective ways to do that is through exhaust heat recovery, which is why we partner with Cain Industries.

Who is Cain Industries

Cain Industries has been designing and manufacturing combustion exhaust heat recovery and boiler economizer systems since 1978. For more than four decades, their work has focused on a single objective: recovering waste heat from boiler and combustion exhaust and converting it into useful applications.

Cain Industries has been designing and manufacturing combustion exhaust heat recovery and boiler economizer systems since 1978. For more than four decades, their work has focused on a single objective: recovering waste heat from boiler and combustion exhaust and converting it into useful applications.

Cain systems are engineered to reclaim heat that would otherwise be lost up the stack and redirect it to boiler feedwater, makeup water, process fluids, or steam. Their product line includes a wide range of economizers and heat recovery solutions purpose-built for industrial and institutional boiler plants.

This singular focus on exhaust heat recovery is what sets Cain apart. It is not an add-on offering. It is the core of their business.

Why We Partner With Cain Industries

We partner with Cain Industries because their expertise aligns directly with our approach to industrial boiler systems: practical efficiency, long-term reliability, and real operating value.

Cain’s economizer systems are engineered for both retrofit and new installations, making them a strong fit for existing boiler plants looking to improve performance as well as new facilities designing efficiency in from day one. Their solutions integrate cleanly into real-world boiler rooms without introducing unnecessary complexity, while still delivering measurable improvements in energy recovery.

Just as important, Cain systems are proven in the field. These are not theoretical efficiency gains. They are systems that consistently perform in demanding industrial and institutional environments.

Turning Lost Heat Into Measurable Value

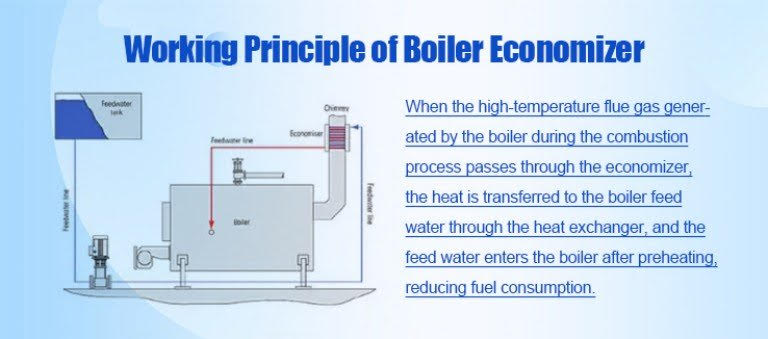

Every boiler produces exhaust heat. Without recovery, that energy simply exits the stack and is lost. Cain economizers are designed to capture those BTUs and put them back to work.

By preheating incoming feedwater or supporting other thermal loads, economizers reduce the amount of fuel required to produce steam. The result is improved boiler efficiency, lower fuel consumption, and reduced operating costs over time.

For facilities operating high-hour or high-load boiler plants, this kind of recovery can have a meaningful impact on overall plant performance and lifecycle cost.

Proven Solutions for Industrial and Institutional Facilities

Cain Industries has built a reputation on systems that work where it matters most: in operating plants with real constraints, real loads, and real uptime requirements. Their economizers are deployed across a wide range of industrial and institutional facilities, helping operators extend equipment life, improve efficiency, and make better use of the energy they are already paying for.

That proven track record is why Cain is a trusted partner in our boiler projects and why its solutions remain a key part of our approach to exhaust heat recovery.

Leave A Comment